Tel

0577-62795555

Tel

0577-62795555

Yes—but only when they are designed for it.

Standard nylon cable ties, commonly white or natural in color, are produced for indoor use. They perform well in offices, control rooms, and enclosed spaces where sunlight is absent. Outdoors, however, the same material behaves very differently.

Ultraviolet radiation attacks nylon at a molecular level. Over time, polymer chains are broken, flexibility is lost, and tensile strength is reduced. The cable tie may still look intact, but internally it is already compromised.

![]()

Cable ties outdoor use therefore requires purpose-engineered cable ties, not standard products used incorrectly.

Many buyers assume cable tie color is cosmetic. In outdoor applications, it is not.

White cable ties are typically made from untreated nylon. They contain no UV stabilizers and no protective additives.

They are suitable for:

Indoor wiring

Temporary fastening

Sheltered environments

They are not suitable for:

Direct sunlight

Long-term outdoor exposure

Critical installations

When exposed to the sun, white cable ties often become brittle within months. Breakage usually occurs during routine inspection or minor movement—precisely when reliability is expected.

Black cable ties are black for a reason.

Carbon black is added during manufacturing. This material absorbs and disperses ultraviolet radiation before it can damage the nylon structure. As a result, the aging process is slowed dramatically.

Black cable ties are therefore used as the default standard for outdoor installations worldwide.

The difference is not aesthetic.

It is structural.

![]()

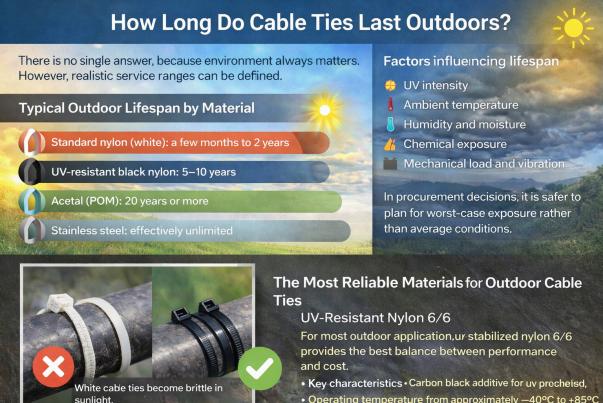

There is no single answer, because environment always matters. However, realistic service ranges can be defined.

Standard nylon (white): a few months to 2 years

UV-resistant black nylon: 5-10 years

Acetal (POM): 20 years or more

Stainless steel: effectively unlimited

UV intensity

Ambient temperature

Humidity and moisture

Chemical exposure

Mechanical load and vibration

In procurement decisions, it is safer to plan for worst-case exposure rather than average conditions.

![]()

For most outdoor applications, UV-stabilized nylon 6/6 provides the best balance between performance and cost.

Key characteristics:

Carbon black additive for UV protection

Operating temperature from approximately -40°C to +85°C . Compatible with common installation tools

Available in many sizes and tensile ratings

This type is widely used in construction, solar, telecommunications, and infrastructure projects.